Recent Projects

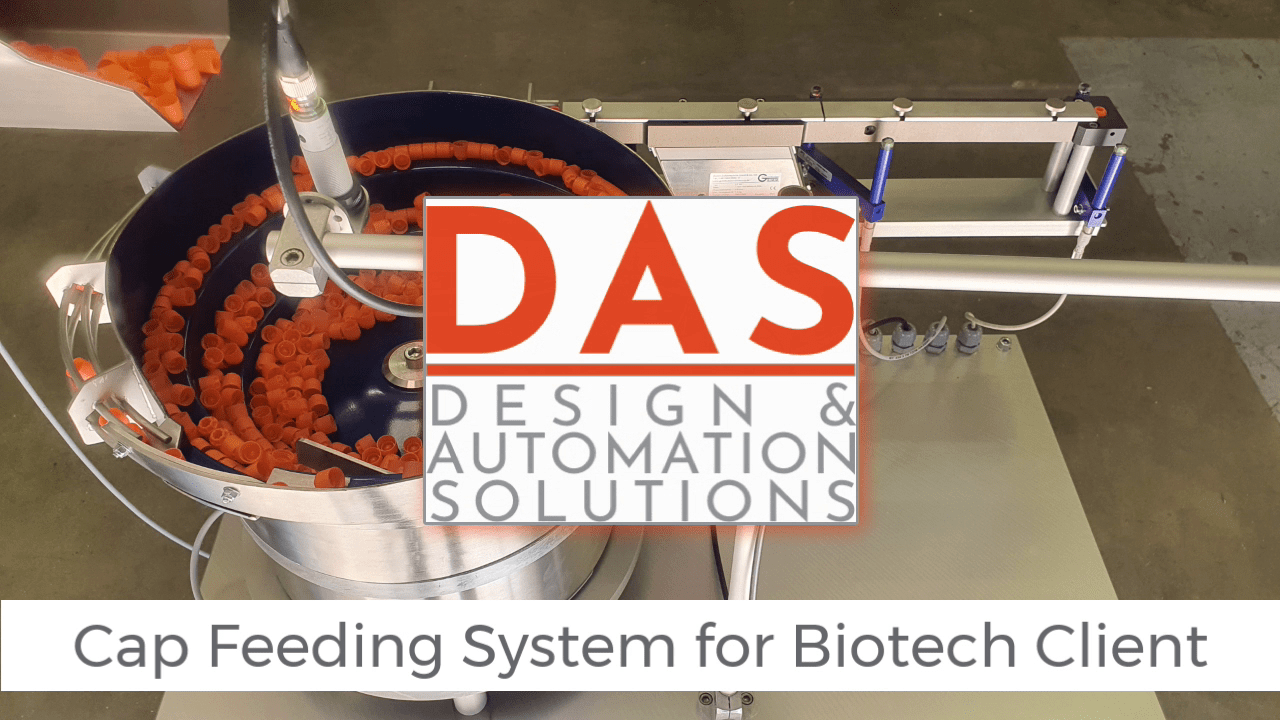

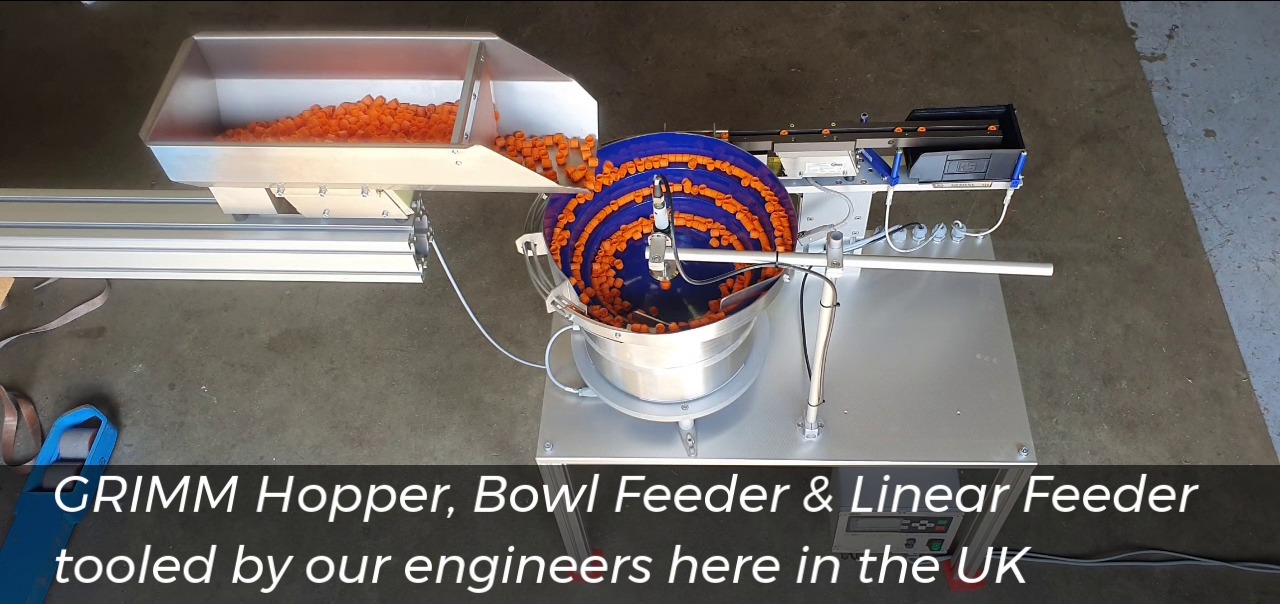

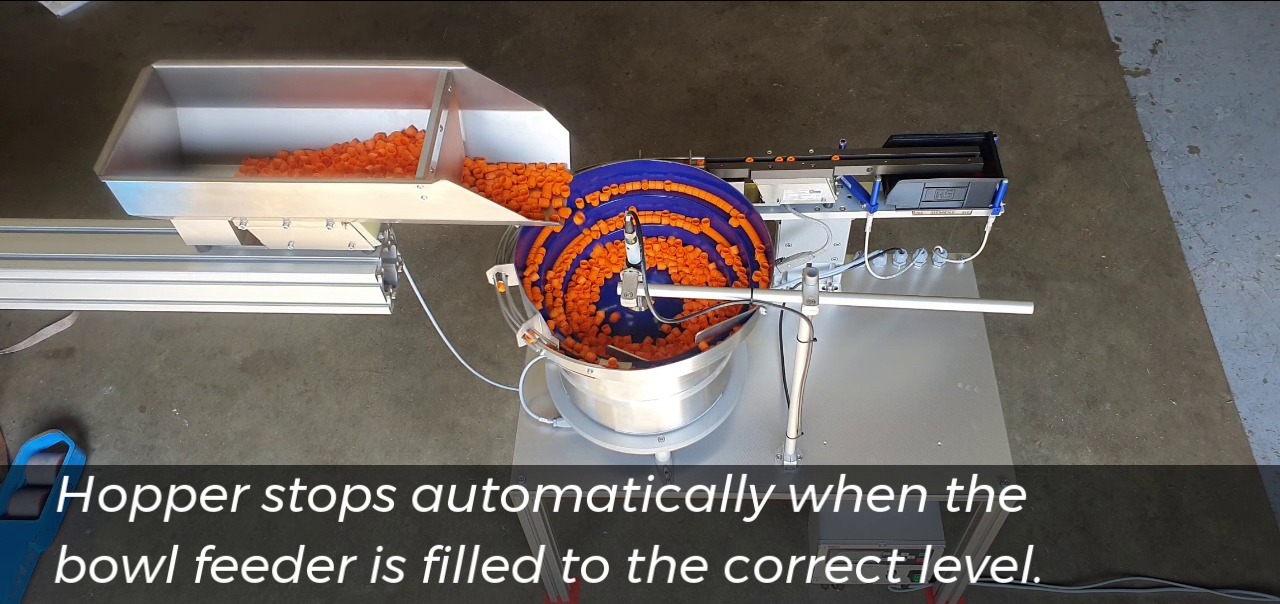

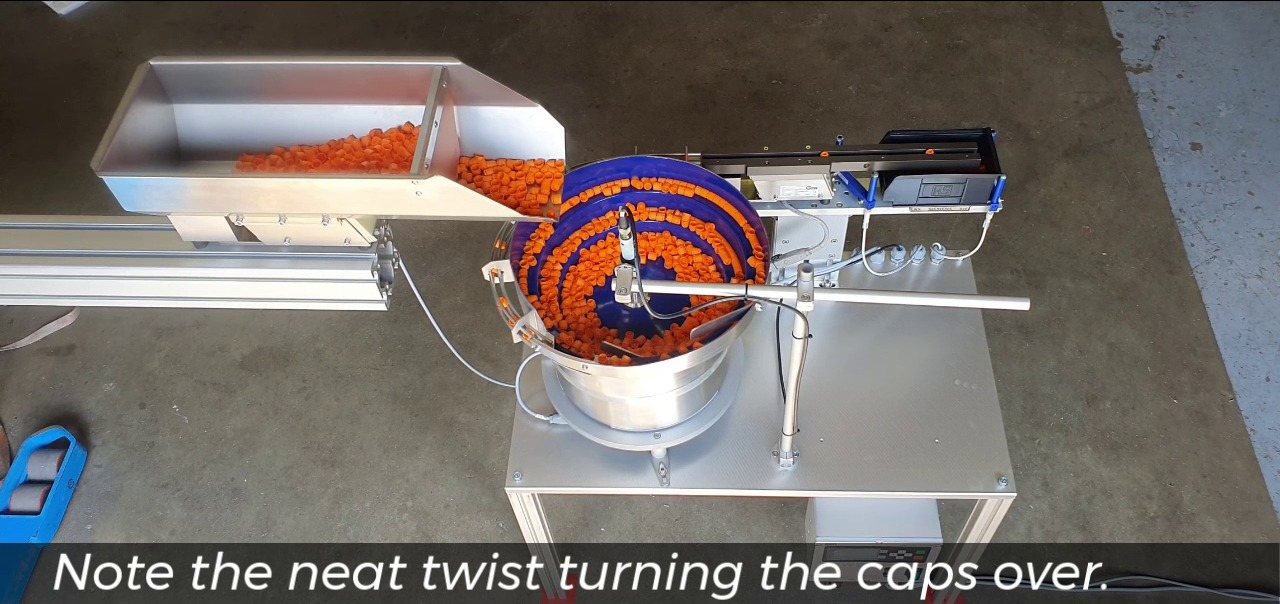

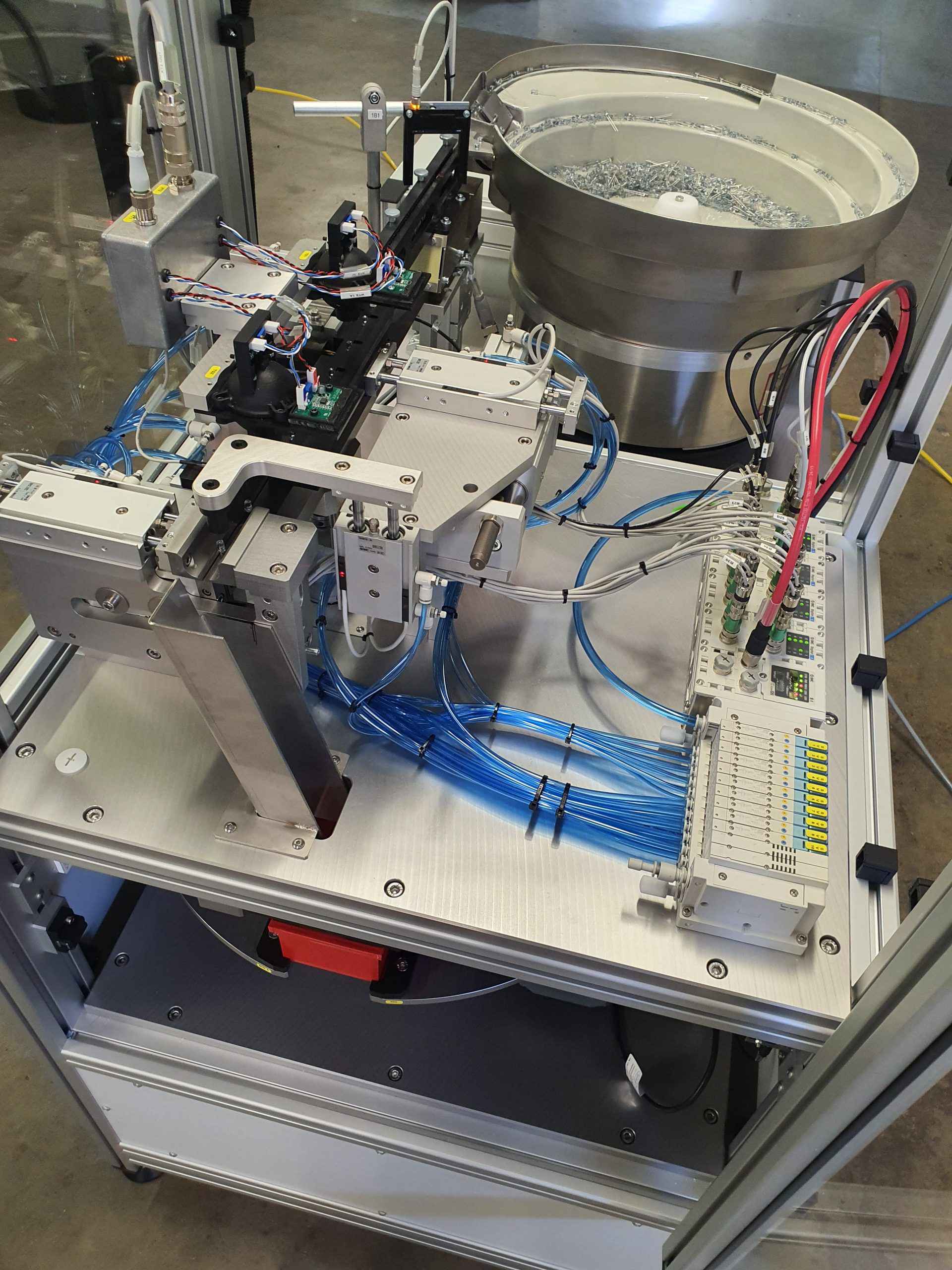

This machine tests, forms and sorts 1800 LEDs an hour into 5 pass grades and fail. The machine feeds the untested LEDs from a Grimm bowl feeder and linear track into our custom testing transfer mechanism. Each infrared LED is tested for brightness and assuming is meets the pass grade is formed before being put into its corresponding graded bin, on the carousel below.

Operator loading the LEDs

LED before and after

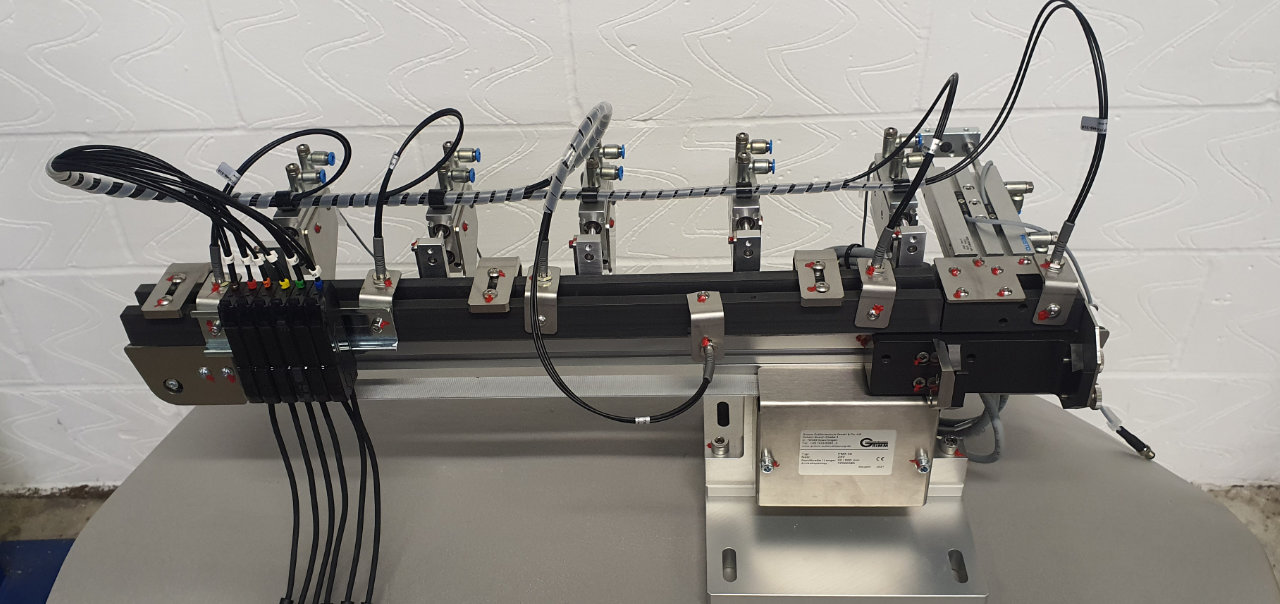

Transfer mechanism, chute & carousel