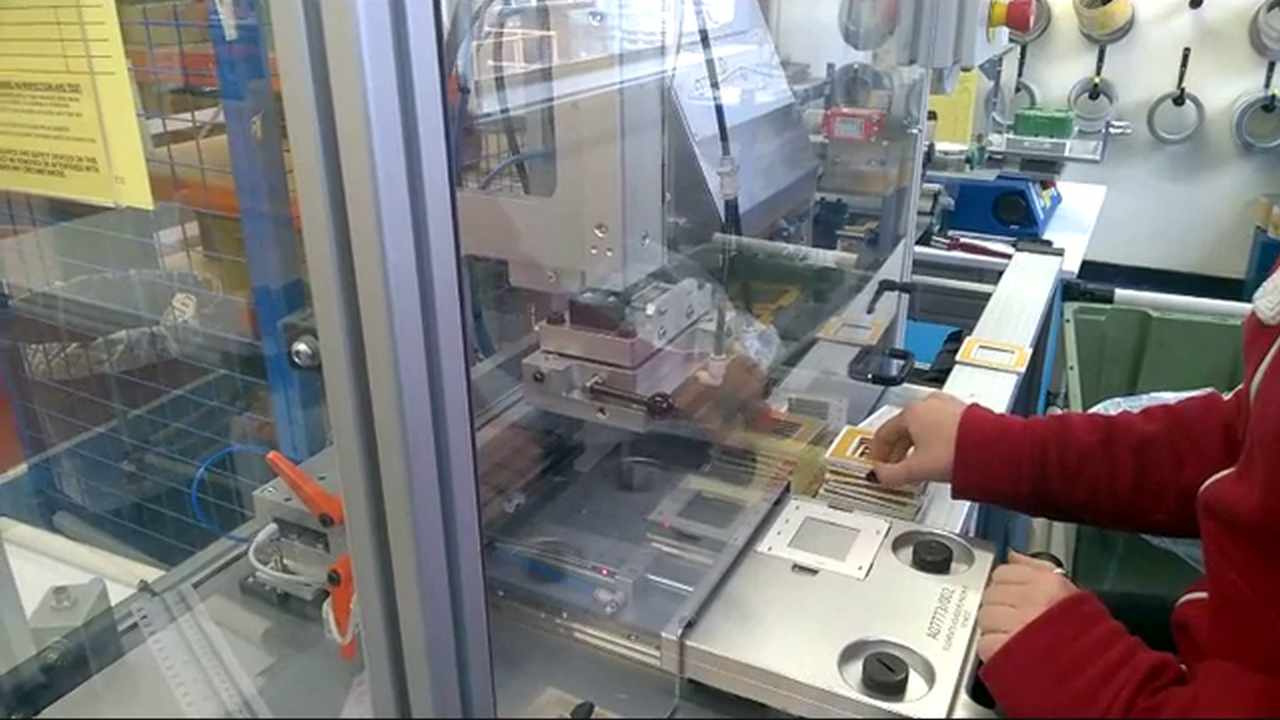

This pneumatic assembly press for speedfit tube fittings has multiple sensors to ensure all the component parts are correctly fitted before assembly is established.

An enhanced design requested by a customer in the fluid control industry, we advanced the technical capabilities to deliver greater accuracy and capacity.

Assembly presses are utilised across multiple industries and we support numerous sectors with our presses.

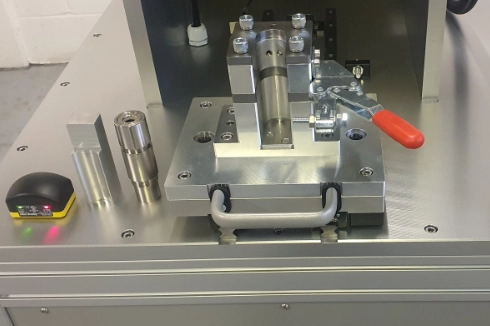

3.5kN Pneumatic Assembly Press

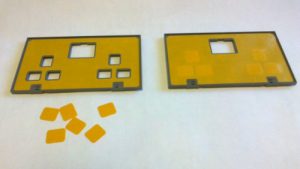

Selector Switch for Different Product Variants

Pressure Gauge to Adjust Insertion Force

Client Tooling and Components

Subsea hydraulics for the oil and gas industry demand exceptional accuracy in extreme working conditions.

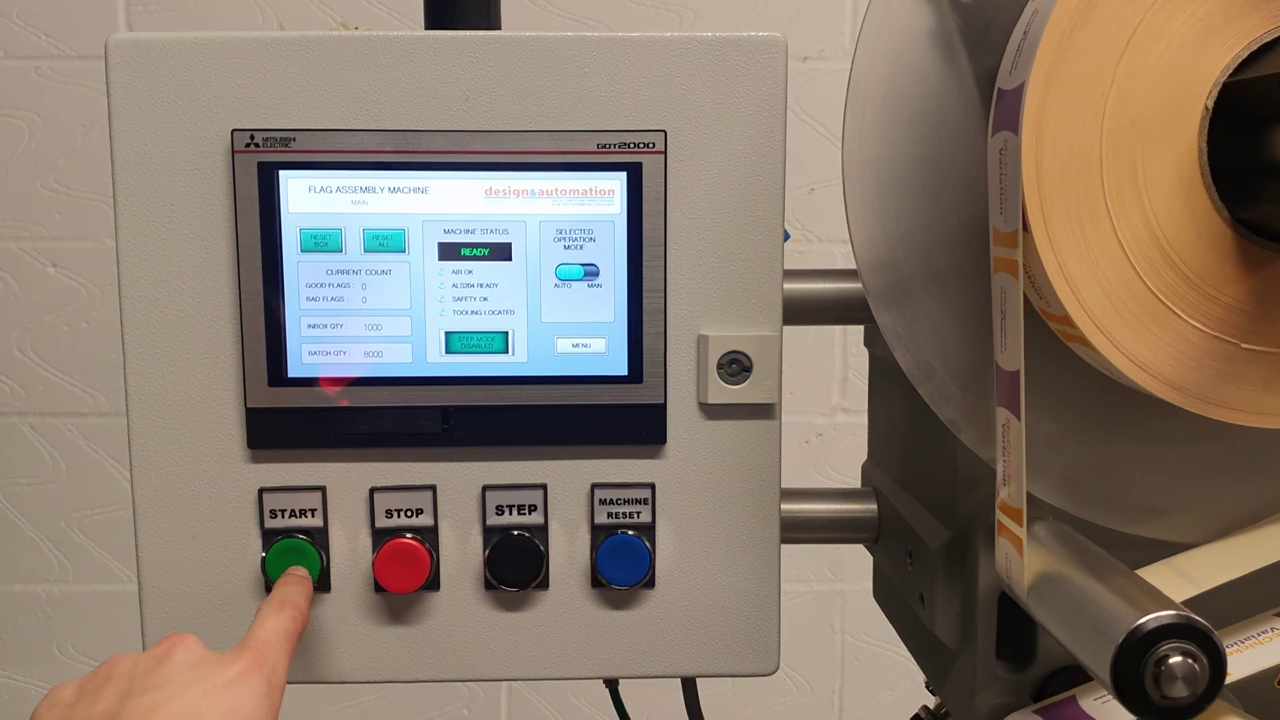

This machine accurately tightens a range of threaded components up to a maximum torque of 800NM with an accuracy of +/- 5NM. A load cell is incorporated to provide the accurate torque measurement in conjunction with a Nord servo gearmotor. The torque values are date and time stamped then recorded in the Mitsubishi PLC/HMI and exported to a customer database.

Delivering incredible accuracy, repeatedly, alongside data acquisition, this machine guarantees full traceability for our oil and gas customer without any risks of human error.

Automated Torquing Machine

Torquing Machine Operator Interface

Load Cell Calibration Fixture

Fixture & Component Ready for Loading

Fixture in Position & Tool Guide

Drive Motor & Load Cell

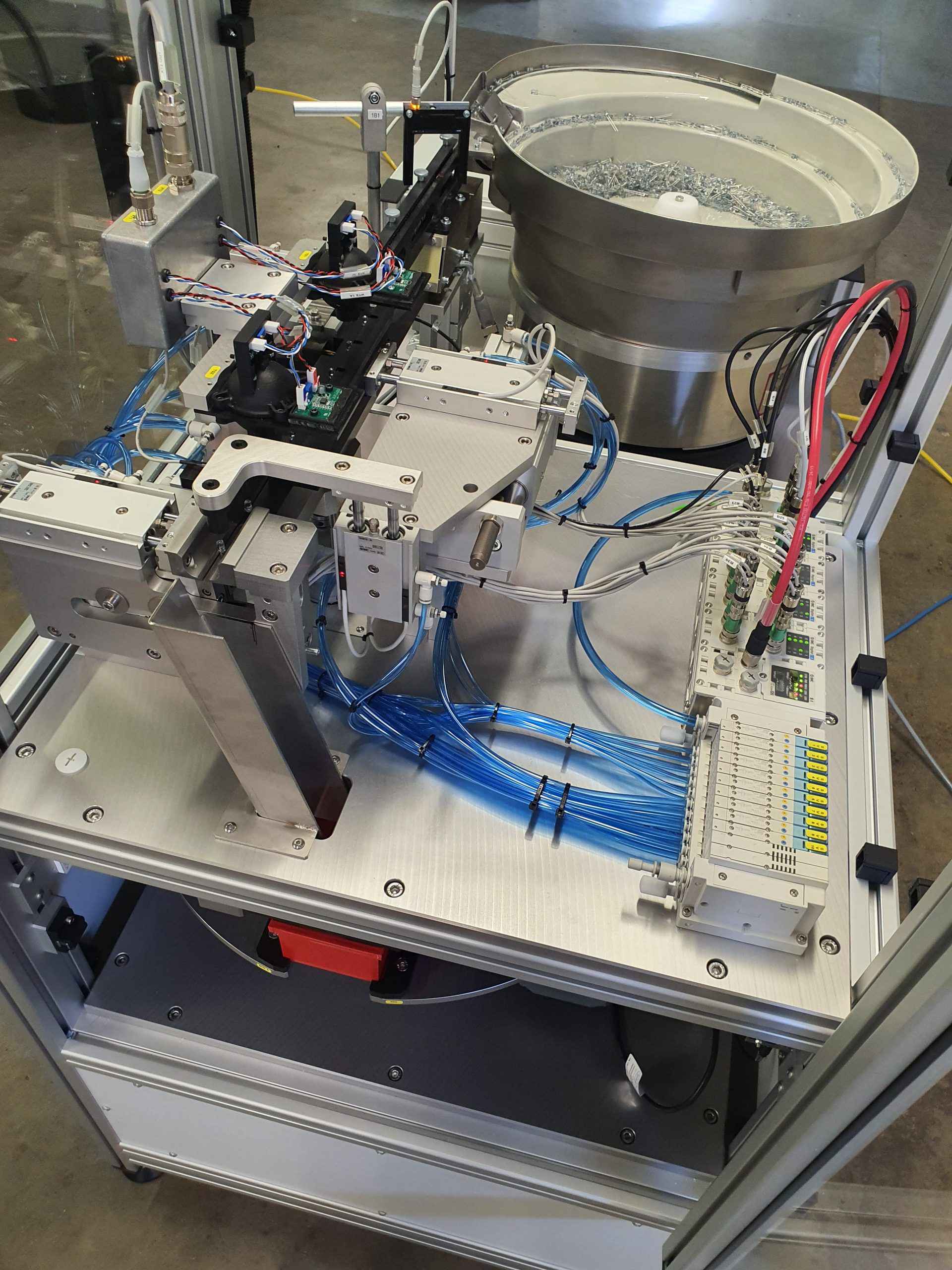

This machine tests, forms and sorts 1800 LEDs an hour into 5 pass grades and fail. The machine feeds the untested LEDs from a Grimm bowl feeder and linear track into our custom testing transfer mechanism. Each infrared LED is tested for brightness and assuming is meets the pass grade is formed before being put into its corresponding graded bin, on the carousel below.

Operator loading the LEDs

LED before and after

Transfer mechanism, chute & carousel

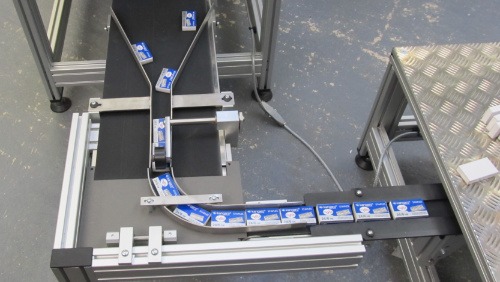

This system automatically produces staples from band made with 250 wires at speeds of up to 320 parts per minute. Working closely with our colleagues at Rudolf Grauer AG in Switzerland we have designed and manufactured a number of systems for the handling and packing of No 10, 24/6, 26/6 and similar staples. The No 10 machine can pack up to 4800 cartons of staples each containing 1000 staples per hour, running 24 hours per day.

No 10 Staple

No 10 Staple Packing Line

No 10 Staple Packing Integration